Pages From Old Telephone Book

Reprinted from "INSULATORS - Crown Jewels of the Wire", January 1976, page 16

Following are a few pages from another old telephone book owned by Chris

Weston of Isle of Wight, England. This information on insulators was printed

about the turn of the century and contains information that we hope will be of

interest to our readers.

3. Insulators.

212. In the manufacture of the insulators two points have to be kept in view.

1st. The material. 2nd. The form.

1. The Material. -- The main object of course in the selection of this is to

find a substance which will offer the greatest possible resistance to the

passage of electricity. Nothing has yet been found which will perfectly

insulate; nor can a theoretically perfect body in this respect ever be looked

for. Porous substances are inadmissible on account of their absorbing moisture

too readily, and being thus transformed into conductors.

A glaze or surface can be imparted to them, but recourse should never be had

to this; only upon bodies which are in every respect suitable should a glaze be

put, and then for the purpose of forming a fine hard surface. A smooth hard

surface is indispensable; with it there is no danger of the wire being worn

through by friction, nor can dirt and dust adhere to the insulator so firmly as

not to be washed off by a good shower of rain.

213. Glass possesses both of the qualifications named above, viz., high

resistance to the passage of electricity and a smooth hard surface; but along

with these it has one inherent disadvantage which is fatal to its employment as

an insulator. It is a very hygroscopic body -- that is to say, it condenses the

moisture from the air very readily, and in a climate such as that of England it

is for this reason altogether unsuitable. The surface of a glass insulator will

be almost always covered more or less with a thin conducting film of moisture.

It is moreover very brittle, and was consequently abandoned in favour of one or

other of its rival competitors. Of late years, however, Mr. Brooks has

introduced in America a form of insulator which is manufactured from blown

glass, and is stated to have given very good results. These he considers to be

mainly due to the 'air surface' of the insulator, nothing but dry air being

allowed to come into contact with it whilst it is being manufactured.

214. Ebonite (1) is another substance which possesses many good points to

recommend it as an insulator. It offers a very high resistance; it is strong,

and when first used possesses a good smooth surface; it has an unassuming

appearance, and so escapes from wilful damage, where glass, porcelain, &c.,

owing to their inviting look, would run the risk of being broken. The great

defect which ebonite labours under, and that which practically precludes its

employment as an insulator when exposed to the weather, is the fact that its surface deteriorates rapidly. Instead of remaining smooth and hard as

when the insulator was first erected, it gradually becomes porous and spongy;

dirt and moisture form upon it, and so deprive the insulator of one of the first

qualities which it ought to possess.

215. Porcelain has been and is still largely employed in the manufacture of

insulators. Its insulating power is high; it possesses a good smooth surface;

and provided it has been perfectly vitrified throughout so as to be homogeneous,

impervious to moisture, and free from flaws, it is eminently adapted for the

formation of an insulator. Porcelain, however, varies very much in its quality;

and unless the manufacture has been thoroughly carried out, with the greatest

care, no reliance can be placed upon it. To all kinds of porcelain a glaze can

be communicated; and so long as this remains good, so long will the insulator

continue to give good results; but immediately the glaze cracks, which it soon

does, moisture enters the mass of it, is porous to any extent, and the value of

the insulator is greatly diminished. Unfortunately there is no means of testing

the manufacture when the insulator is new and the glaze has been imparted to it,

except by breaking it, and the integrity of the manufacturer has therefore to be

solely relied upon.

216. Brown Earthenware is the material from which most of the insulators

employed at the present day in England are formed. It does not insulate so

highly as good porcelain, nor can it be so perfectly glazed, but it is produced

with greater uniformity of quality, and its manufacture can be more thoroughly

relied upon. It possesses the further advantage of cheapness over the materials

which have been already named.

217. 2. The Form. -- Equally important as the material of which an insulator

should be composed is the form which should be given to it. In considering this

the main object to be kept in view is the same as in the selection of the

material, viz. the highest possible resistance to a leakage of the current; at

the same time the strength of the insulator as a support must not be altogether

lost sight of. Seeing, however, that the insulators have little more than the

weight of the wire to withstand, except at the terminal posts, no trouble is

experienced in suiting the form of insulator to this. The main difficulty which

has to be surmounted is the leakage which takes place more or less at every

support; every insulator is to a certain extent a fault, and the magnitude of

the fault depends upon the form which the insulator possesses. The passage of a

current of electricity through the wire depends upon the gauge of the latter; it

is a function of its mass. The same cannot be said of the insulator; the

resistance to the path of the current, instead of depending upon the mass of the

insulator, is mainly a question of surface. The most perfect form of insulator

will be that in which the surface exposed is a minimum, and the wire is as far

as it can be from the insulator's support, due allowance being of course made for the insulator itself being

sufficiently strong.

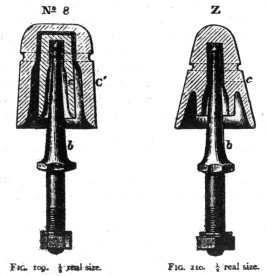

218. Numerous forms have from time to time been tried; that which is in

general use in England with the brown earthenware is shown in fig. 109. It

consists of two distinct and separate cups c and c', which are fitted into each

other by means of a cement composed of equal parts by weight of fine Pit sand,

Portland cement, and plaster of Paris. Into the inner cup c a galvanized iron

bolt b is inserted and fixed by means of a cement composed of

5 parts by weight of clean river sand, sifted.

3 parts by weight engine ashes (from an old engine fire-box).

2 parts by weight pine resin.

A groove is cut on the surface of the outside cup, and into it the line wire

is placed and firmly bound, as will be afterwards explained. This form of

insulator combines several advantages, to which attention may briefly be drawn.

Whatever current escapes from the wire in the groove must make its way over

the entire surface of both cups before it can reach the bolt, By having two cups

again; greater reliance can be placed upon the quality of the earthenware; the

two small pieces can be better burnt and vitrified than one larger portion; and

the probability of flaws or faults occurring in such cup is very remote. At the

same time by means of this arrangement one portion of the insulator is open to

the cleansing action of the rain which serves to remove any dust or dirt apt to

adhere to it; whilst the other is kept dry, and in wet weather continues to

offer considerable resistance to any escape of the current.

219. Another form of insulator employed in England on minor lines is that

known as the 'Z' insulator, and shown in fig. 110 it closely resembles the form

already described, and differs from it in having a double cup c all formed of

one piece of earthenware instead of two separate cups fitted into each other.

220, When the insulators have to be protected from either wilful or

accidental damage, such as that occasioned by stone-throwing and the like, it is

customary to cover them with an iron cap, and bind the wire into a small lug

upon the surface of it. The inconvenience attending the use of iron caps is

occasioned by the accumulation of dust, insects, &c., beneath the hood: the

iron cap protects them from the cleansing influence of the rain, and so leads in

time to a deterioration of the insulation. An effort has been made to get over

this by cutting slits in the iron cap, and although this has to some extent

remedied the evil, yet only where actually rendered necessary by either of the

causes named above should iron-capped insulators be had recourse to.

221. Great difficulty is invariably experienced in preserving the insulation

upon those lines which skirt the seacoast no matter what material is employed or

what form of insulator is adopted. The insulator becomes coated with salt, which

being more or less moist, conducts in all except the driest possible weather.

The difficulty is greatly increased when the wind is from the sea. Upon no

account should iron-capped insulators be made use of upon such lines as these;

advantage should be taken of the rain to the utmost for washing the salt from

off the outside surface at least of the outer cup; it materially improves the

insulation. Wire covered with tarred tape or hemp is occasionally employed in

extreme cases of this nature; but by chaffing against the insulator the tape or

hemp gradually gets rubbed off, and leaves the wire exposed just at the point

where protection of this nature is most required. Open wires skirting the

sea-coast should therefore be resorted to only when no other route by which they

might be carried is available.

(1) Ebonite is a mixture of two or three parts of sulphur and five parts of

caoutchouc baked for several hours at 170 degrees F. under a pressure of four or

five atmospheres.

|